Bill Calfee

Gun Fool

Playing with this V-3

CYA friends:

We're in an interesting new world with this new V-3.

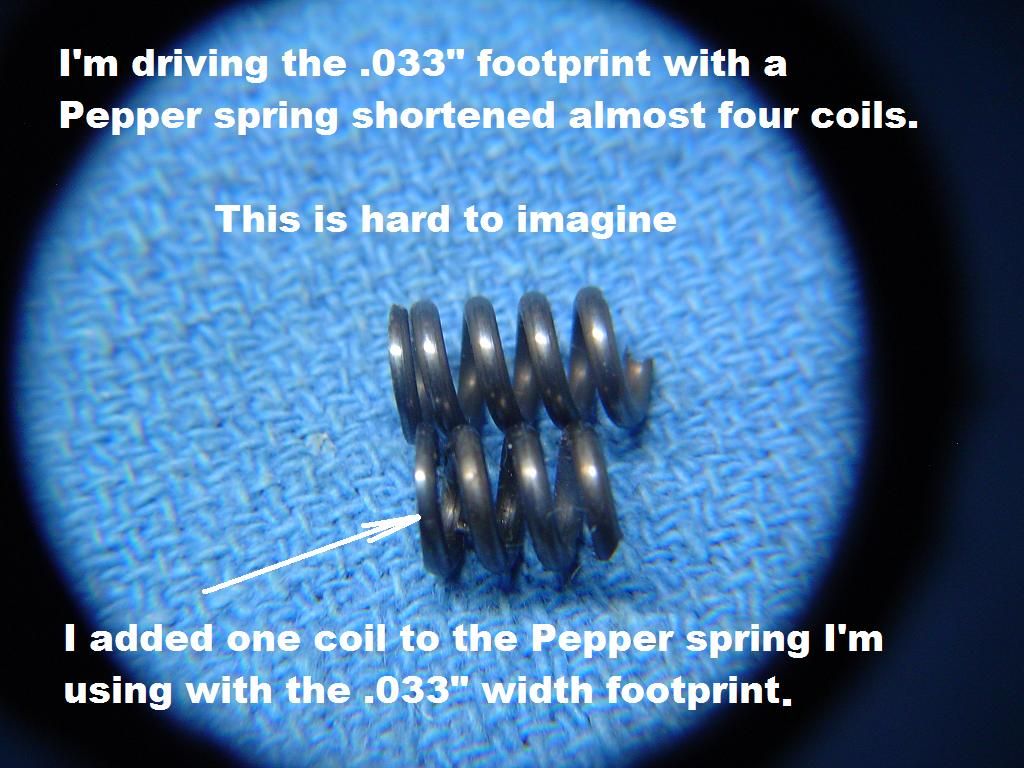

We used to search for higher and higher rate springs.......

With this thing being so beautifully free, I'm now searching for smaller and smaller rate springs.

______________________

This is for Az_Speed, and other creative folks who do their own work, or would like to.

The pin of the V-3 is hard.....which means it's wear proof.

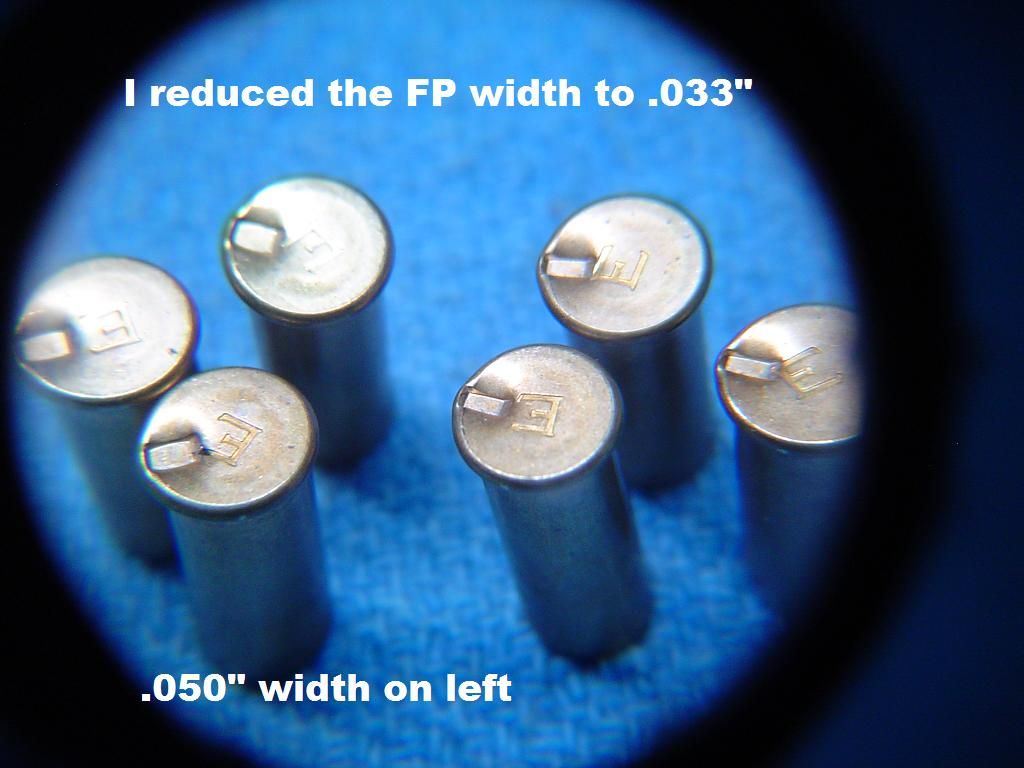

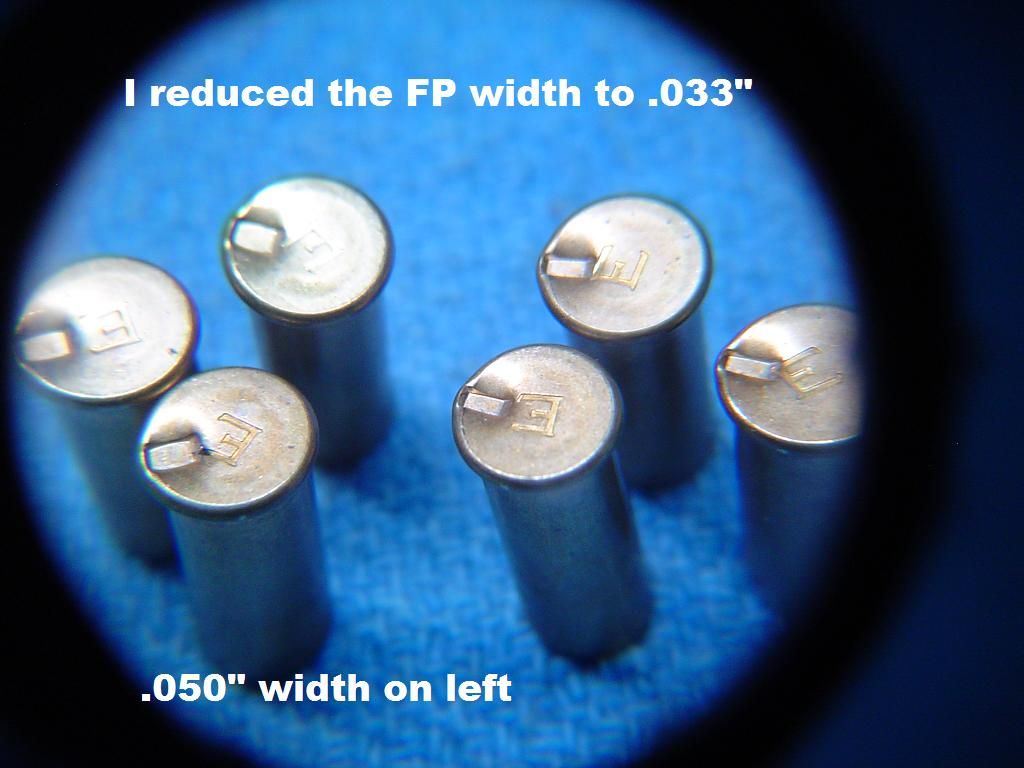

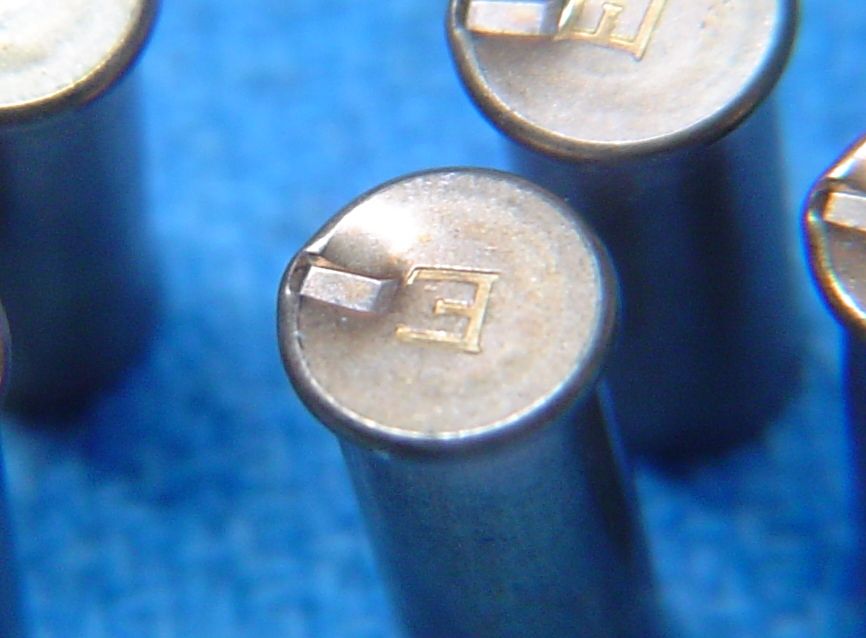

And I used to have to grind pins like this...

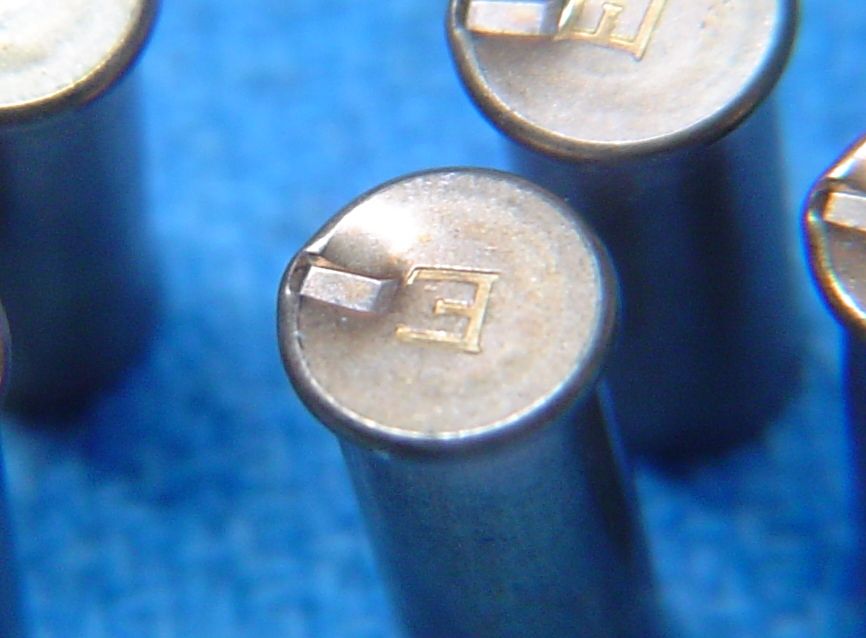

But this time I reduced this pin tip using the two diamond needle files Jeff Patterson gave me...

And it was so easy, and so much more accurate than the way I used to have to grind hard pins..

__________________________

I've got more I want to say.......

Too much for right now, as I've got something I have to do this afternoon...

But I'll get back to it.....

Again, this unbelievably free V-3 is a whole new world to explore.

There's a lot that I'm liking about this action........

But this "free" thing is one of the most impressive....it's opened up some new doors...

Your friend, Bill Calfee

_______________________________

You know, I ain't used to fancy tools....like these diamond needle files...

I have fought hand grinding hard pin tips for years....

And these diamond needle files made it so easy, and accurate...

Unless I'm mistaken, this is the width the V-3 will come standard with now.....or very close to it.

CYA friends:

We're in an interesting new world with this new V-3.

We used to search for higher and higher rate springs.......

With this thing being so beautifully free, I'm now searching for smaller and smaller rate springs.

______________________

This is for Az_Speed, and other creative folks who do their own work, or would like to.

The pin of the V-3 is hard.....which means it's wear proof.

And I used to have to grind pins like this...

But this time I reduced this pin tip using the two diamond needle files Jeff Patterson gave me...

And it was so easy, and so much more accurate than the way I used to have to grind hard pins..

__________________________

I've got more I want to say.......

Too much for right now, as I've got something I have to do this afternoon...

But I'll get back to it.....

Again, this unbelievably free V-3 is a whole new world to explore.

There's a lot that I'm liking about this action........

But this "free" thing is one of the most impressive....it's opened up some new doors...

Your friend, Bill Calfee

_______________________________

You know, I ain't used to fancy tools....like these diamond needle files...

I have fought hand grinding hard pin tips for years....

And these diamond needle files made it so easy, and accurate...

Unless I'm mistaken, this is the width the V-3 will come standard with now.....or very close to it.

Last edited: