Bill Calfee

Gun Fool

Chambers, it's time to call a spade a spade....

CYA friends:

I'm probably going to upset some of the RFBR schmidts of the world, but, 90% of the chambers RFBR schmidts cut, are not perfect...

And I'm not leaving myself out, either.

_________________________________

My buddy Wally, after being in my shop yesterday watching me cut a "perfect" chamber, has agreed to write about his experience, and post it here on CYA.

Everyone involved with serious rimfire accuracy will want to know what he has to say..

And what Wally does say in his story, will be his interpretation of exactly what he saw.......without any input from me as what to say....

___________________________

One other point.........finished chambers are more difficult to read for centering and the degrading of the leade, that are "as cut" chambers.

But, even with finished chambers, I guarantee you I could read every chamber in RFBR today, and show that 90% of them are not perfect.

And once again, I'm not excluding myself...

________________________

So let's learn how to detect a "perfect" rimfire accuracy chamber.

______________________

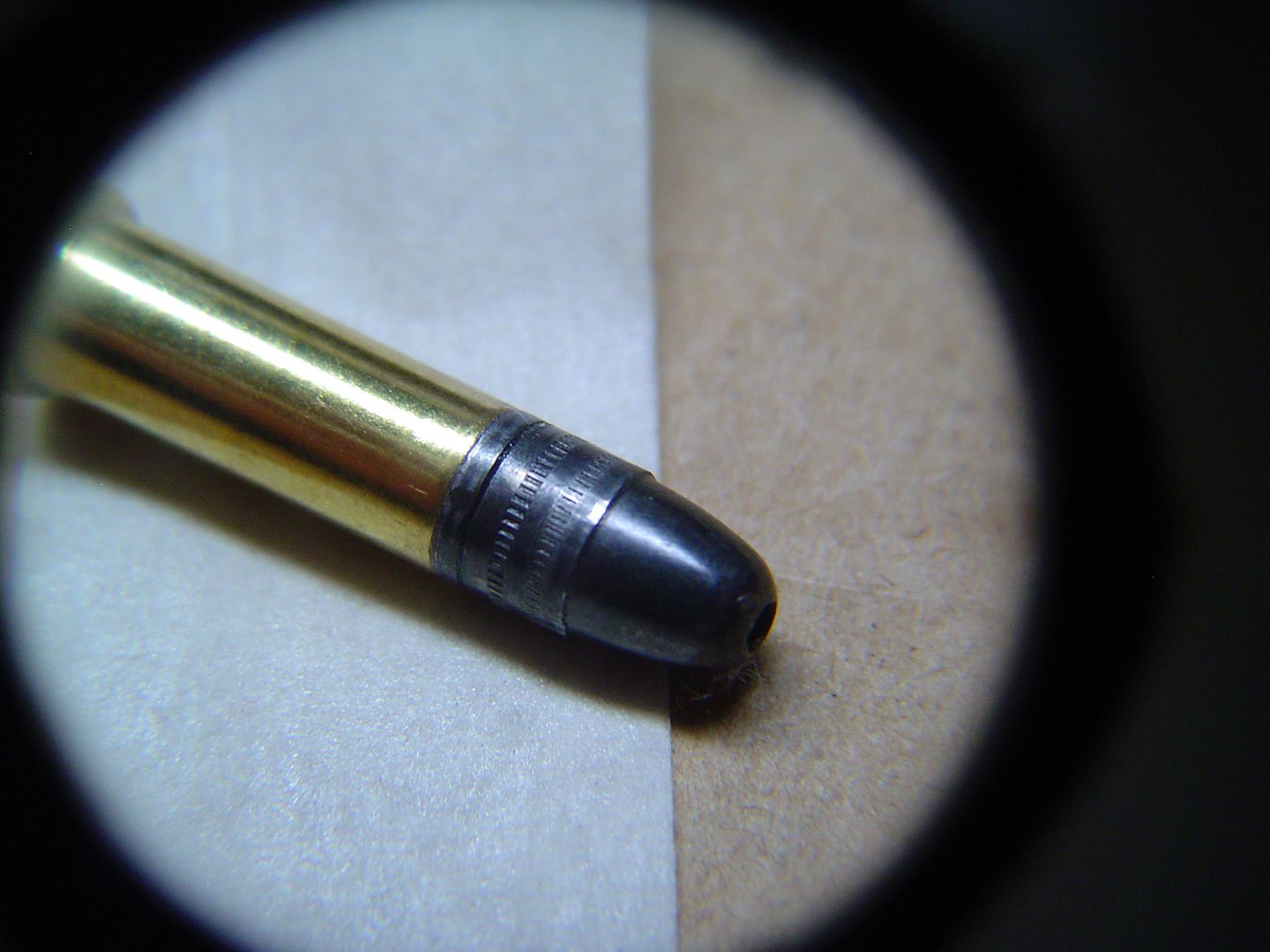

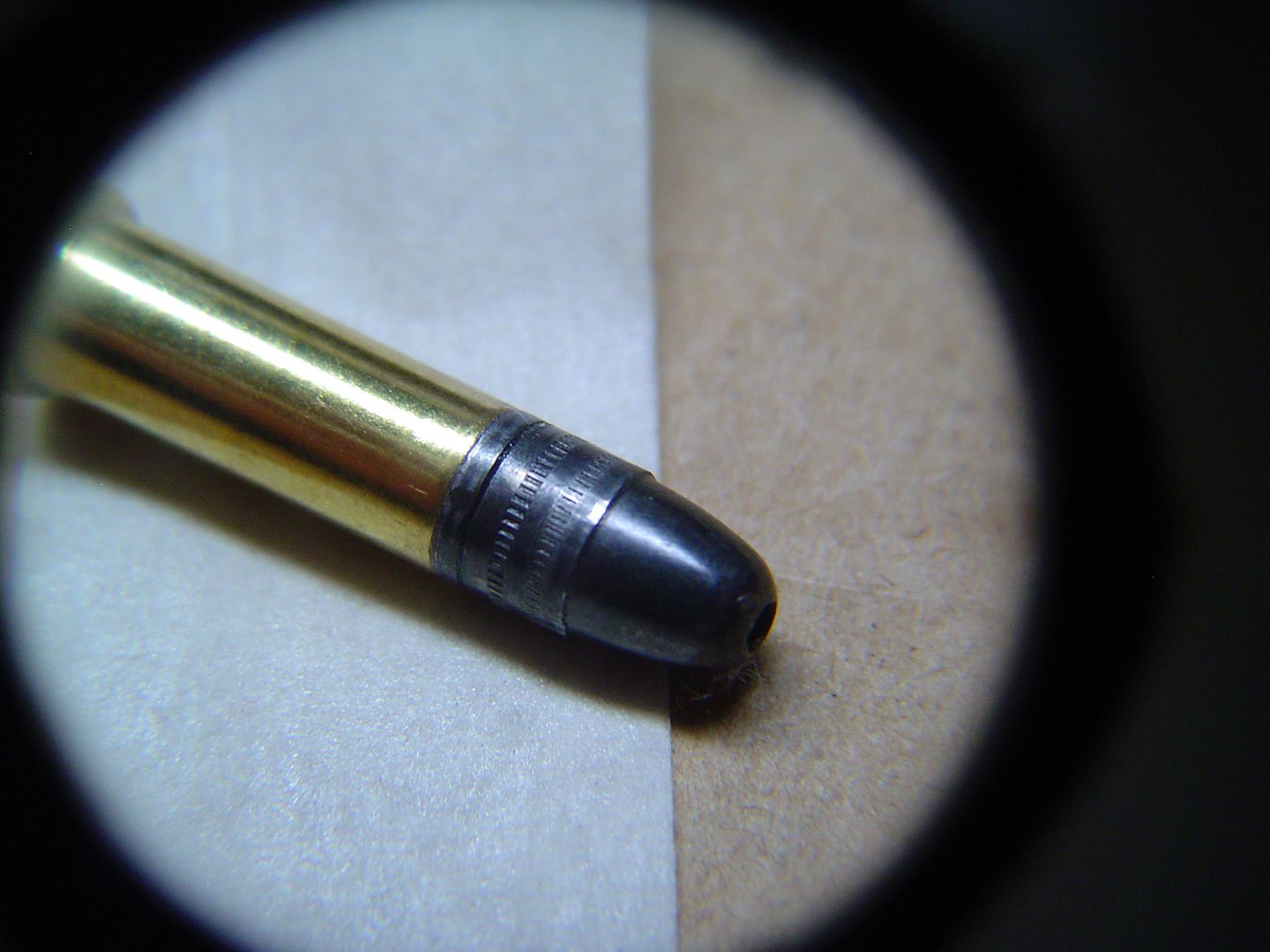

I spent about an hour today, taking close-up pictures of the live rounds that I inserted, then removed, from the "perfect" chamber I cut with Wally yesterday.

I must have taken 100.....

But only two show what I want......

Below are these two pictures........unedited.....

________________________________

As soon as I have time, I'm going to edit them, and point out some markers that show a "perfect" chamber.

This to go along with Wally's story, describing watching me cut a "perfect' chamber yesterday..

Your friend, Bill Calfee

_______________________

These two pictures are from about a hundred I took today trying to get a good closeup, are unedited, for now.....I'll edit them later..

One other thing....

If you're serious about rimfire accuracy, look closely at these two pictures and see if you can detect how these two pictures demonstrate a "perfect" rimfire chamber.......

Look closely, I'll give you a hint:

The wax serration grooves..........look closely.....what do you see?

_____________________________

___________________________________

CYA friends:

I'm probably going to upset some of the RFBR schmidts of the world, but, 90% of the chambers RFBR schmidts cut, are not perfect...

And I'm not leaving myself out, either.

_________________________________

My buddy Wally, after being in my shop yesterday watching me cut a "perfect" chamber, has agreed to write about his experience, and post it here on CYA.

Everyone involved with serious rimfire accuracy will want to know what he has to say..

And what Wally does say in his story, will be his interpretation of exactly what he saw.......without any input from me as what to say....

___________________________

One other point.........finished chambers are more difficult to read for centering and the degrading of the leade, that are "as cut" chambers.

But, even with finished chambers, I guarantee you I could read every chamber in RFBR today, and show that 90% of them are not perfect.

And once again, I'm not excluding myself...

________________________

So let's learn how to detect a "perfect" rimfire accuracy chamber.

______________________

I spent about an hour today, taking close-up pictures of the live rounds that I inserted, then removed, from the "perfect" chamber I cut with Wally yesterday.

I must have taken 100.....

But only two show what I want......

Below are these two pictures........unedited.....

________________________________

As soon as I have time, I'm going to edit them, and point out some markers that show a "perfect" chamber.

This to go along with Wally's story, describing watching me cut a "perfect' chamber yesterday..

Your friend, Bill Calfee

_______________________

These two pictures are from about a hundred I took today trying to get a good closeup, are unedited, for now.....I'll edit them later..

One other thing....

If you're serious about rimfire accuracy, look closely at these two pictures and see if you can detect how these two pictures demonstrate a "perfect" rimfire chamber.......

Look closely, I'll give you a hint:

The wax serration grooves..........look closely.....what do you see?

_____________________________

___________________________________

Last edited: